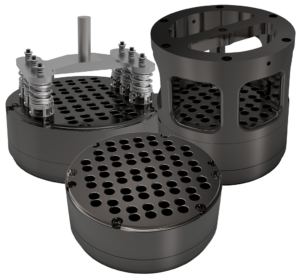

STRAIGHTFLO™ SE COMPRESSOR VALVES

BEST-IN-CLASS VALUE

The StraightFlo™ SE valve is a drop-in replacement compressor valve designed to deliver exceptional performance and unmatched value for reciprocating compressors. They are ideal for upstream and midstream oil and gas applications, as well as industrial gas services such as air, nitrogen, and hydrogen.

RIGHT DESIGN, RIGHT MATERIAL

The StraightFlo™ SE (Standard Edition) valve features the same proven Modular Reed Valve technology in our renowned StraightFlo™ SS (Severe Service) valve, but with economical 4140 alloy steel housings and corrosion-resistant coating.

You save up-front with a lower installed cost—and down the line with ongoing savings from extended run times, lower fuel costs, increased throughput, and reduced inventory costs.

StraightFlo™ SE valves are for compressor speeds from 200 to 3600+ rpm, pressure differentials up to 4,350 psi (300 bar), service temperatures from -40° to 500°F (-40° to 260°C), and for non-corrosive or mildly corrosive gases including sweet and sour natural gas, air, NGL, and industrial gases.

GAME-CHANGING PERFORMANCE

Reliability

5x-35x longer service interval (2x guaranteed)

Serviceability

About 15 minutes, on-site, with no machining

Performance

2-15% lower compressor power / greater throughput

Inventory Savings

Up to 80% lower

inventory costs

ESG

Reduced emissions, fuel efficiency, 10x lower vibrations/noise levels

Durable 4140 alloy steel provides long, trouble-free service life for housings. A corrosion-resistant coating provides an extra level of protection.

StraightFlo™ SE valves, there’s no wear and no need for machining—ever. That’s because Modular Reed Technology eliminates impacts between the sealing elements and the housings.

We back every StraightFlo™ SE valve with a limited 10-year warranty on the valve housings. There’s no better protection for your valves… or your investment.