FREQUENTLY ASKED QUESTIONS

+ Increase Production, Reliability, Run Time, Revenue & ROI

+ Lower Maintenance Costs, Inventory, Fuel & Power Consumption

+ Reduce Flaring, Noise, Vibrations & Environmental Impact

WHAT IT IS

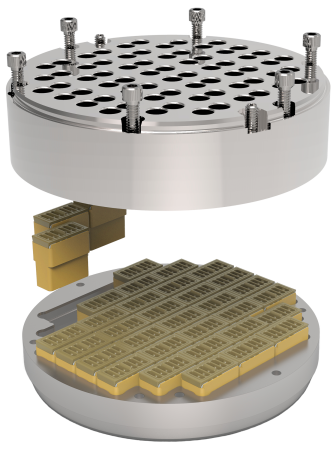

The Atlas Copco StraightFlo™ Valve is a drop-in replacement valve for industrial reciprocating compressors for speeds from 200 to 3600+ rpm, pressure differential across a valve to 4350 psi (300 bar), service temperatures from -40o to 482oF (-40oC to 250oC), and for all gases including sweet and sour natural gas, acid gas, CO2, hydrogen, nitrogen, ethylene, air, ammonia, HCl etc.

This revolutionary technology is patented around the world and offers significant improvements over conventional valves.

FREQUENTLY ASKED QUESTIONS

A compressor valve opens and closes with every compression cycle. The timing and pattern of these events are referred to as valve dynamics. It is important that the valve opens and closes at the right time and does not flutter. Compressor valve dynamics influence valve life and compression efficiency. Springing and the mass of the moving components affect valve dynamics. For proper performance, valves are designed for specific operating windows.

Volumetric efficiency. Volumetric efficiency (VE) of a compression cylinder may be influenced by a valve conversion. Clearance volume affects VE. Clearance volume is the volume in a cylinder end that is not swept by the movement of the piston. Depending on the size of the cylinder, clearance volume can range from 2% to as high as 60% of displacement, or more. It includes spaces between piston and head at the end of the stroke, space under the valves, and of course clearance within the piston side of the valve itself.

The higher the clearance the poorer the volumetric efficiency of the cylinder.

The equivalent area is the orifice area in square inches of a valve which also has a given pressure loss. The potential performance differences of two valves can be established by comparing their equivalent areas.

The higher the equivalent area, the better the flow efficiency.

Compressor operators typically expect the valve to be:

- efficient

- durable

- quiet

Efficiency demands include aerodynamic flow efficiency and the volumetric efficiency. A durable valve should provide maintenance free operation over several thousand hours plus relative ease in servicing and repair

A compressor valve regulates the flow of air or gas in a compressor cylinder. There is at least one suction valve and one discharge valve for every compression chamber. Each valve opens and closes with every cycle of the piston. For example, a valve used in a compressor operating at 1200 r.p.m. for 24 hours a day and 365 days a year, opens and closes:

72,000 times per hour, or

1,728,00 times per day, or

630,720,000 times per year!

There are several different kinds of compressor valves: plate valves, ring valves, channel valves, feather valves, poppet valves, ball valves, reed and concentric valves. Each design has specific criteria with regard to the sealing element and all the other components are designed accordingly.

Most valves have five basic components:

- Seat

- Guard (guard, stop plate, buffer, plate, etc.)

- Sealing element (valve plate or valve ring, channel, poppet, feather strip, ball, etc.)

- Damping element (coil springs, cushion plates, spring plates, damping plates, etc.)

- Assembly element (bolts, nuts, retainer ring, etc.)