Jack Bolt Eliminator™

JACK BOLT ELIMINATORS

SECURE, RELIABLE, SIMPLE TO MAINTAIN

Are your reciprocating compressor valves held in place by jack bolt restraints? Then you’re leaking fugitive emissions and profitability.

But there is a safe and effective solution.

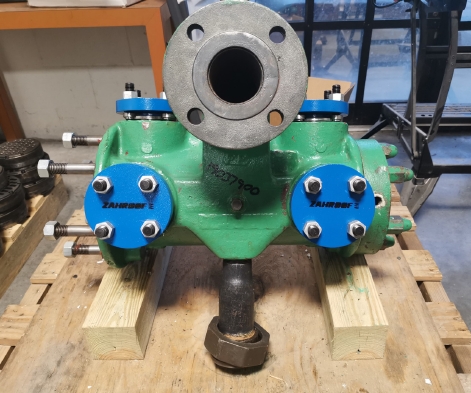

Atlas Copco Jack Bolt Eliminator kits convert valves to a modern cage and O-ring design with a gas-tight sealing surface. The conversion takes about 15 minutes per valve, with no machining or cylinder modification required. And once installed, the conversion ring doesn’t have to be removed to service the valve.

jack bolt eliminators:

why they're better

Problems With Compressor Valve Jack Bolts

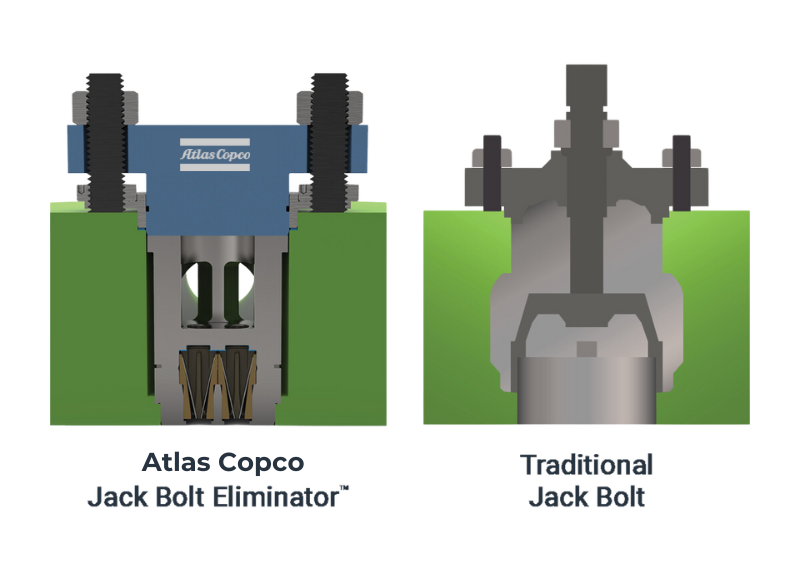

Many vintage compressors use a jack bolt to apply force to the valve cage (chair) and hold the valve in place.

There are many serious problems with this design including:

- The valve cover or jack bolt backing off, resulting in a loose valve which causes damage and/or a gas leak

- The seal nut backing off, causing leakage around the jack bolt

- A complicated torqueing procedure which, even when followed correctly, can cause issues resulting in gas leakage or part damage.

- With this design, it’s easy to over-torque the jack bolt, causing leaks at the valve seat gasket, a bent jack bolt or galled threads, or damage to the cage and/or valve

In the jack-bolt system, the valve cap bolts compress the gasket under the valve cap. The jack bolt then compresses the gasket under the valve. The second process, however, relieves pressure on the gasket under the cap, which can cause leakage.

In fact, there are three leak paths in a jack bolt design:

- The gasket between the valve and the cylinder

- The gasket between the valve cap and cylinder

- Through the threads of the jack bolt and valve cap

Because of these issues, jack-bolt style valve assemblies have been eliminated from modern compressor designs.

But what about legacy machines?

Jack Bolt Eliminators: A Solid Solution

Atlas Copco’s Jack Bolt Eliminator converts a legacy jack-bolt-restrained valve to a cap-cage-restrained valve with an O-ring cap – the design now used in modern compressors.

The Jack Bolt Eliminator consists of three components:

- Valve Cover

– Eliminates the threaded hole for the jack bolt.

– Allows a simple torqueing procedure - JBE Assembly Conversion Kit

– Includes a conversion ring that remains in place when the valve is removed

– Provides a sealing surface for the O-ring

– A gasket seal against the cylinder body remains permanently installed - Jack Bolt Eliminator Integral Cage Valve

The elastomeric O-ring seals radially against a machined surface on the cylinder valve port. The valve cap sits on a cylindrical cage that pushes down on the valve and the gasket between the valve and cylinder when the valve cap bolts are torqued.

Unlike the jack bolt design, crushing of the gasket between the valve and cylinder can occur without affecting the seal between the valve cap and cylinder (the O-ring seal). This makes it simple to install and maintain.

ADVANTAGES FOR COMPRESSOR OPERATORS

ESG

Eliminates leak paths to reduce emissions

Reliability

Solid and secure valve retention

Savings

Reduces maintenance costs

Installation

Installs in about 15 minutes, on-site, with no machining

SOLID VALVE RETENTION FOR ANY LEGACY APPLICATION

Atlas Copco Jack Bolt Eliminator conversion kits are available for compressors with legacy jack bolt valve restraints, including:

- Ajax

- Blackmer

- Dresser Rand

- Ingersoll Rand

- Gardner Denver

- Penjax

- Worthington