ENERGY EFFICIENT

ENERGY EFFICIENT

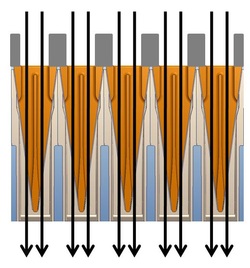

STRAIGHT THRU-FLOW, HIGHEST EFFECTIVE AREA

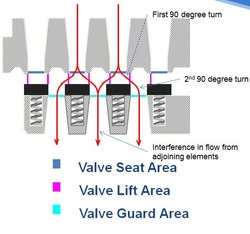

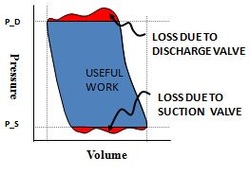

The flow through a StraightFlo™ valve has almost negligible deviation of the gas stream with very low resistance to flow and hence very low pressure drop. This is unlike a conventional valve where the flow makes at least two right angles while traversing the valve.

The flow through one module of a StraightFlo™ valve is independent of the flow through its adjacent module. In conventional valves, such as poppet valves or ring valves, the flow past a poppet or ring interferes with the flow past the adjacent poppet or ring, causing large losses. In a ported plate valve, the flow through a port in the plate interferes with the flow through an adjacent port in the plate causing losses.

There is no pre-load acting on the reeds of the modules of StraightFlo valves that have to be overcome for the gas to start flowing. This means that StraightFlo™ valves have almost zero cracking pressure unlike conventional valves where the sealing elements (poppet/plate/ring) are pre-loaded by one or multiple springs. This means even less resistance to flow.

The above factors result in StraightFlo™ valves having the highest effective area among all compressor valves, typically 40 – 60% more for our standard valves. However, for our StraightFlo™ HEV (High Efficiency Valve), the effective area is increased over 100% compared to conventional valves on account of more modules being used within the same valve diameter.