Reduce Operating Costs

with StraightFlo™ valve

MINIMIZE OPERATING COSTS

with StraightFlo valve

Minimize Fuel Costs

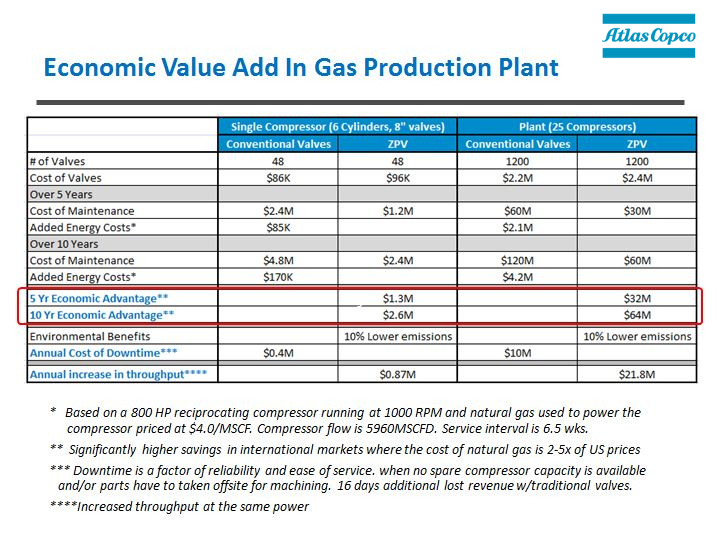

- With the highly efficient StraightFlo™ valve, fuel costs can be reduced considerably.

- In the case of a typical pipeline transmission compressor running at 1000 rpm, the fuel consumption is reduced by 10%.

- With a reduction in fuel, there is a corresponding reduction in emissions.

- Operations can decide to increase the throughput through the compressor and keep the power/fuel the same.

Minimize Service Costs

- The StraightFlo™ valve design eliminates wear on the seat and carrier. Never machine or replace your valve seat or carrier, the most expensive part of the valve. There is a 10 year warranty on the valve seat and carrier.

- Simply replace the old modules with new ones, in the field, on-site, to return your valves to factory new condition. Eliminate machining, off-site repair, special tools and skilled labor.

- 2 – 5X improvement in service interval with StraightFlo™ valves means less downtime for servicing valves. It also reduces emissions due to blow down of pipes, venting, purging and flaring.

- Minimize Downtime and Loss of Revenue

- With the enhanced reliability of the StraightFlo™ valve and the improvement of the compressor MTBS by 5 to more than 10X, minimize the compressor downtime and the resulting loss in production/revenue.

Minimize Inventory Costs

- Stock boxes of modules instead of racks and racks of expensive assembled valves for all makes and models of compressors, cylinders and operating conditions. About 5 – 6 module part numbers are sufficient for a company to service all its compressor valves, in all regions, at all operating conditions.

- Reduce inventory by 80%. Minimize inventory foot-print and weight.

- Minimize cost of inventory management and risk of obsolescence of inventory.

Minimize Capital Costs

- Never replace the metal housing. Servicing a valve is done within minutes at the compressor site. This makes it unnecessary to buy spare valves with the modular StraightFlo™ valve.

- When field conditions change over time, replace the modules to get an optimum valve for the new conditions. Eliminate having to purchase a new set of valves.

- By increasing throughput in existing compressors by 3 – 18%, eliminate the need for a new compressor to meet higher flow demands. Or, decommission one or more existing compressors.