STRAIGHTFLO™

COMPRESSOR

VALVES

UNMATCHED PERFORMANCE. UNPRECEDENTED ESG BENEFITS.

Increase Production, Reliability, Run Time, Revenue & ROI

Lower Maintenance Costs, Inventory, Fuel & Power Consumption

Reduce Flaring, Noise, Vibrations & Environmental Impact

SAME TECHNOLOGY, TWO MATERIAL OPTIONS

GAME-CHANGING TECHNOLOGY

The StraightFlo™ valve is a drop-in replacement for OEM valves in reciprocating compressors operating at speeds from 200 to 3600+ rpm, pressure differentials up to 4,350 psi (300 bar), and service temperatures from -40° to 500°F (-40° to 260°C). They are effective with all gases, including sweet and sour natural gas, acid gas, CO2, hydrogen, nitrogen, ethylene, air, ammonia, HCl etc.

This revolutionary technology is patented around the world and offers significant improvements over conventional valves.

INCREASES IN INCREMENTAL REVENUE BY HUNDREDS OF THOUSANDS TO MILLIONS OF DOLLARS

REDUCES POWER CONSUMPTION BY 5—15%

UP TO 12% THROUGHPUT IMPROVEMENT

REDUCES SERVICES COSTS; ALL BUT ELIMINATES UNSCHEDULED COMPRESSOR DOWNTIME

REDUCES INVENTORY COSTS BY AS MUCH AS 80%

REDUCES NUMBER OF EMISSION EVENTS AND FUGITIVE EMISSIONS INTENSITY

SUPERIOR PERFORMANCE, INCREASED RELIABILITY, EASIER REPAIRS

Whether you’re doing equipment service callouts yourself or managing those who do, StraightFloTM valves make your job a lot easier. Compared to conventional compressor valves, revolutionary StraightFlo™ valves perform substantially better, run significantly longer, require far less maintenance, and are fast and simple to service… guaranteed.

5x to 35x

Up to 15%

HOW IT WORKS

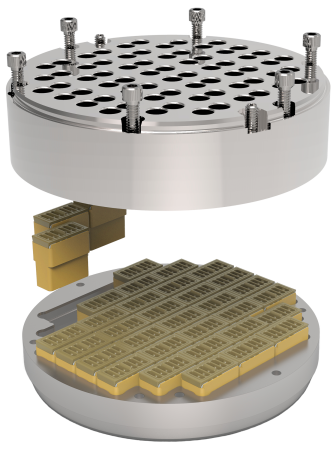

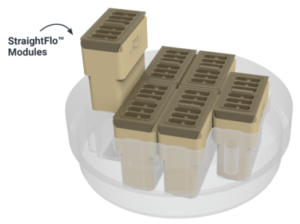

Our modular design features interchangeable modules held stationary between the valve seat and carrier. There are 12 standard modules in 3 materials, each with varying reed lift and stiffness, so StraightFlo™ valves can cover all speeds and operating conditions of existing compressors and be optimized for any given application.

Optimized For You

We use our proprietary Dynamic Valve Sizing Program to determine the optimum module for your situation. This program simulates valve operation in the cylinder for the given application, using NIST real gas properties to calculate the reed displacement, velocity, and acceleration to determine valve opening and closing impact forces. Our engineers then select a module whose impact forces are within design limits while offering maximum reed lift and effective area. The result? Maximum efficiency without compromising reliability.

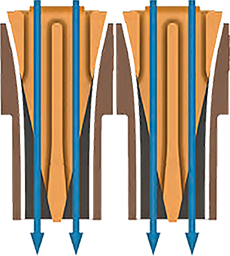

REED VALVE MODULES WITH A STRAIGHT-THROUGH FLOW PATH

With StraightFlo™ valves noise can be reduced by 6-8dB.

Resonance Resistance

HIGHLY TOLERANT DESIGN

The straight-through flow path makes our valves self-cleaning and highly tolerant of liquids and solids in the gas stream. When the reeds are wide open, liquids and solids go right through the module without any impact on the critical sealing faces. With conventional valves, liquids and solids strike hot, highly stressed plastic, often resulting in embedded particles and breakage. This degrades the sealing surface to the point where the valve must be serviced. With StraightFlo™ valves, that never happens.

EASY TO SERVICE,

NO NEED FOR SPARE VALVES

Always OEM Spec

No machining means the valve seat pressure rating never drops below that of the new valve.

It also eliminates the chance of machining errors that result in tolerance stack up and prevent valves from being installed during service.

INTERCHANGEABLE, EASY TO RECONFIGURE

StraightFlo™ modules are truly interchangeable between valves, whether they’re 1.5″ in diameter or greater than 14″; whether they’re suction or discharge valves; whether the valve goes into a cylinder made by Manufacturer X or Manufacturer Y.

They’re also easy to re-rate for a new application—just change out the present modules with modules rated for the new application. As long as the valve seat is pressure-rated for the new application, you now have a valve for a brand new application at very little cost.