STRAIGHTFLO™ SS COMPRESSOR VALVES

SUPERIOR RELIABILITY

StraightFlo™ SS (severe service) valves provide unmatched reliability, efficiency, serviceability, and savings in the most demanding downstream applications.

Manufactured with durable stainless steel housings, StraightFlo™ SS valves provide reliable performance with highly corrosive gases encountered in refining, petrochemical, chemical and fertilizer applications.

The StraightFlo™ SS is a drop-in replacement for OEM valves in reciprocating compressors operating at speeds from 200 to 3600+ rpm, pressure differentials up to 4,350 psi (300 bar), and service temperatures from -40° to 500°F (-40° to 260°C).

STEP-FUNCTION IMPROVEMENT

On-Site Service, No Need for Spares

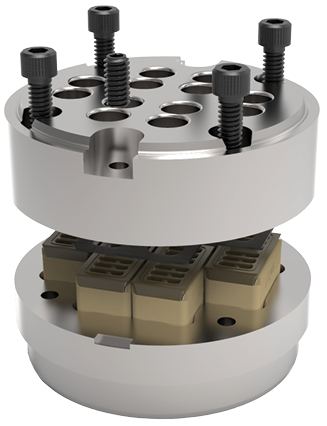

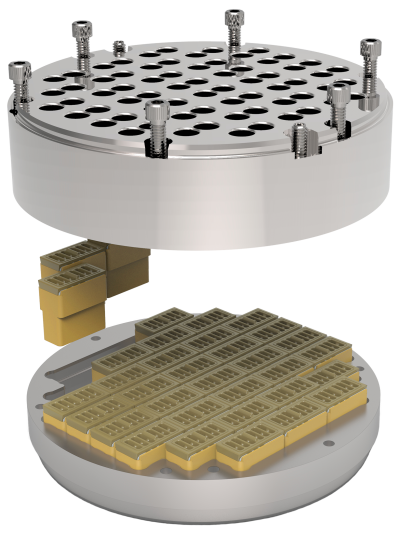

The revolutionary springless design of the StraightFlo™ valve features interchangeable, enhanced reed valve modules held stationary between the valve seat and carrier. Unlike conventional ring, plate, or poppet designs, the sealing components in StraightFlo™ valves do not move or impact the metal housings.

Normal wear-and-tear is completely contained inside the modules. So housings never need machining.

In fact, StraightFlo™ valves are completely refurbished on site, in minutes, simply by replacing modules. There’s no need to send out valves for repair. And no need for expensive inventories of spare valve assemblies.

Increased Efficiency & Tolerance

Reed valve modules have a straight-through flow path. Since gas doesn’t travel a tortuous path, StraightFlo™ valves have the highest effective area for a given diameter.

The straight-through flow path also makes our valves self-cleaning and highly tolerant of liquids and solids. When the reeds are wide open, liquids and solids go right through the module without any impact on the critical sealing faces.

GAME-CHANGING PERFORMANCE

Reliability

5x-35x longer service interval

Serviceability

About 15 minutes, on-site, with no machining

Performance

2-15% lower compressor power / greater throughput

Inventory Savings

Up to 80% lower

inventory costs

ESG

Reduced emissions, fuel efficiency, 10x lower vibrations/noise levels

IMPROVED SUSTAINABILITY

StraightFlo™ valves provide a wide range of benefits to support your net-zero initiatives.

- Up to 15% emissions reduction

- Up to 15% lower power consumption

- Elimination of multiple blowdown, purging, and flaring events

- 10X less vibration

- 6-8 dB lower noise levels

- Lower carbon footprint from fewer service call-outs

- Reduced energy and materials waste by eliminating valve machining

* All valve performance statements are based on documented case studies.